Types of molds we manufacture at IDM

Each IDM project involves a preliminary study to understand the client's needs in detail and provide the most appropriate solution.

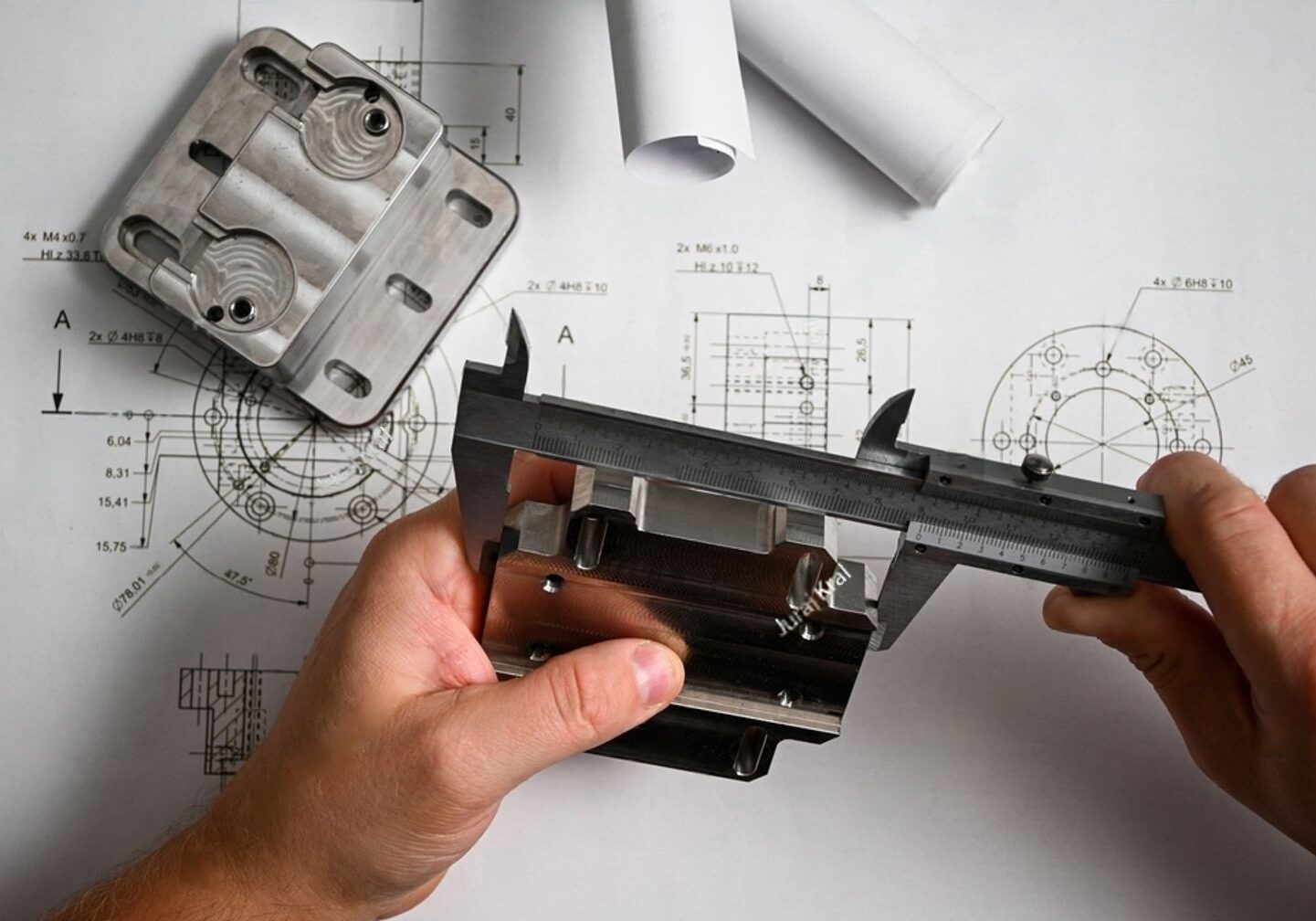

We carry out the complete design of the mold, consulting with the foundry/injector on the most appropriate options for each case, and we also handle the machining and subsequent verification.

Experts in mold making

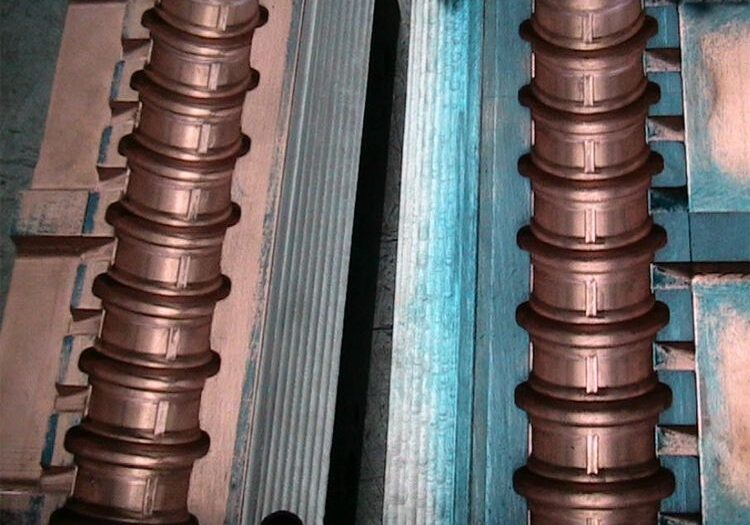

Special Machining

At our company, we rely on the latest technologies to provide greater precision and versatility to each project. We have specific machinery with the latest technology on the market to provide excellent service to our customers.

We adapt to each project, providing the most appropriate solutions to manufacture the desired plastic and aluminum molds or to create the necessary machining.

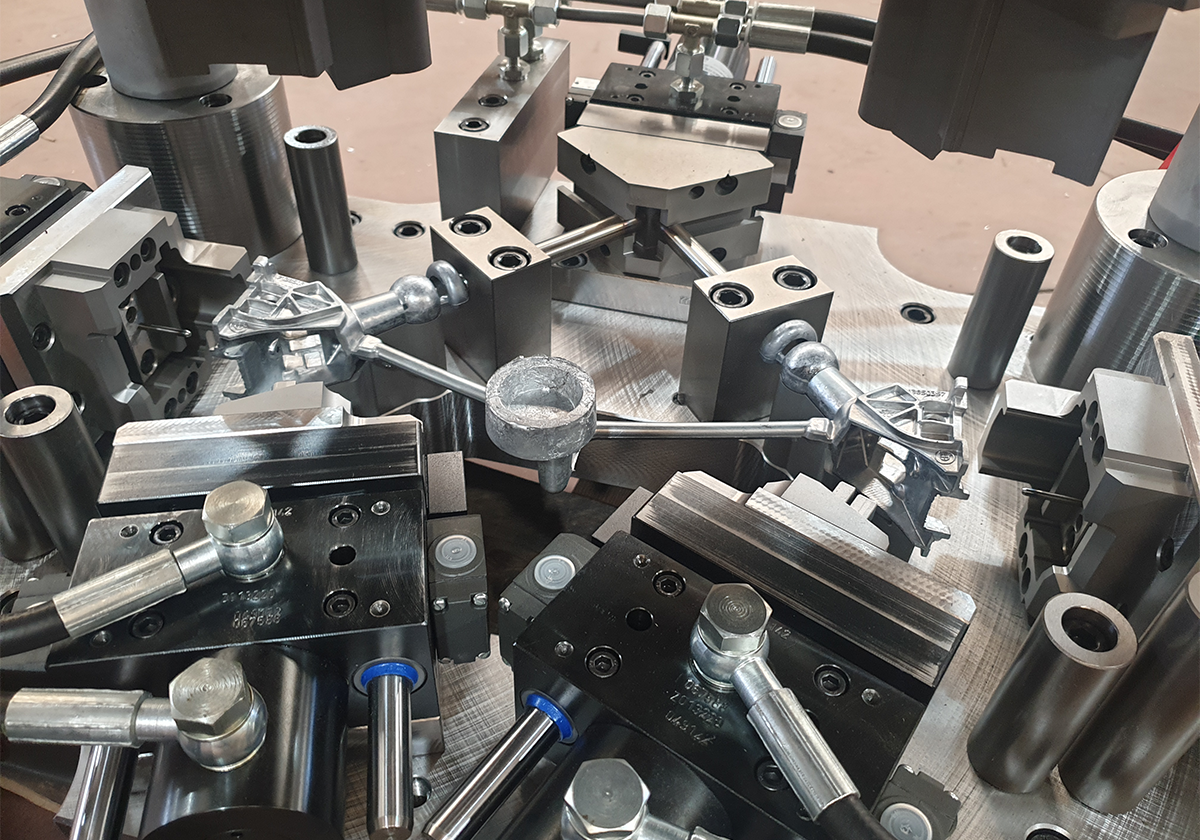

Advanced Deburring Die Manufacturing

Our deburring die manufacturing process combines CAD/CAM design, high-precision CNC machining, and specialized heat treatments. This allows us to create dies that meet our customers' most demanding requirements, optimizing their deburring processes and reducing costs.

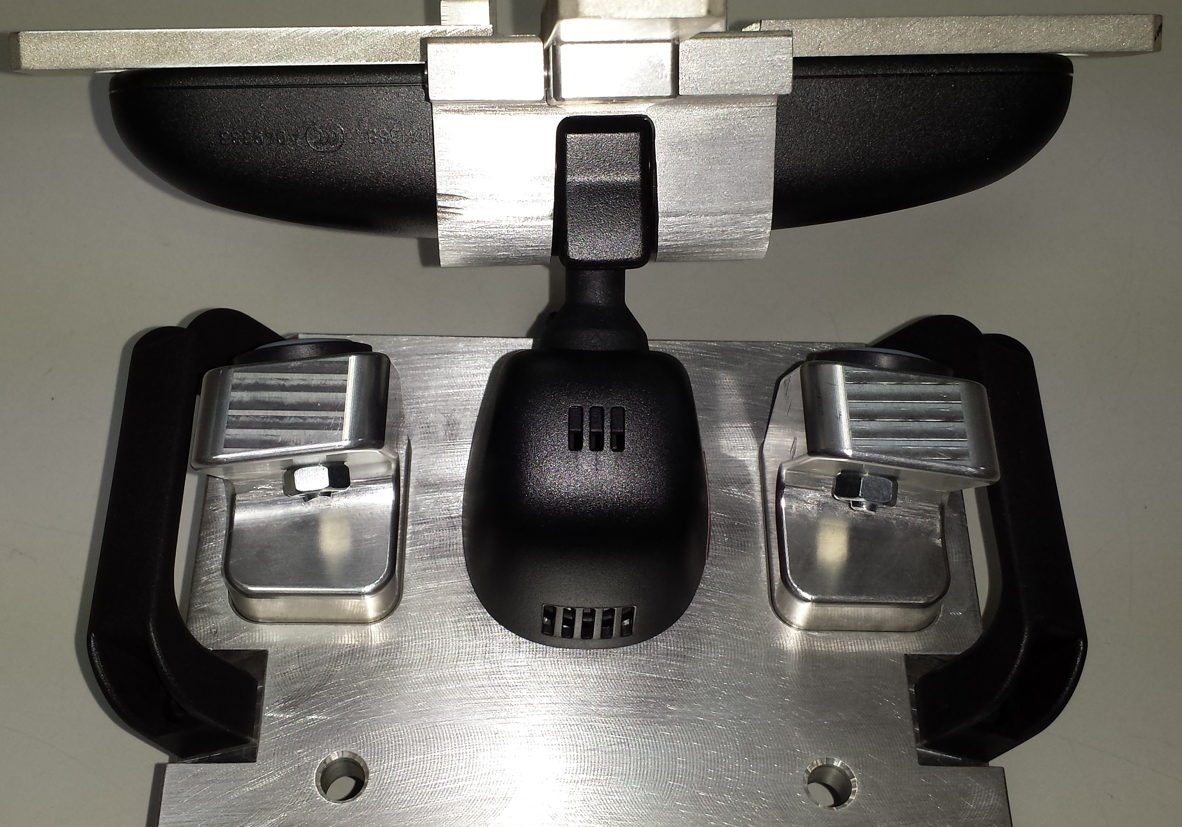

Design and manufacture of inspection fixtures

We also offer tools for subsequent work and tools for verifying finished parts. We also work with all types of materials, including steel, aluminum, and plastics, and we have the necessary technology to manufacture any prototype, regardless of its geometry, size, or precision.

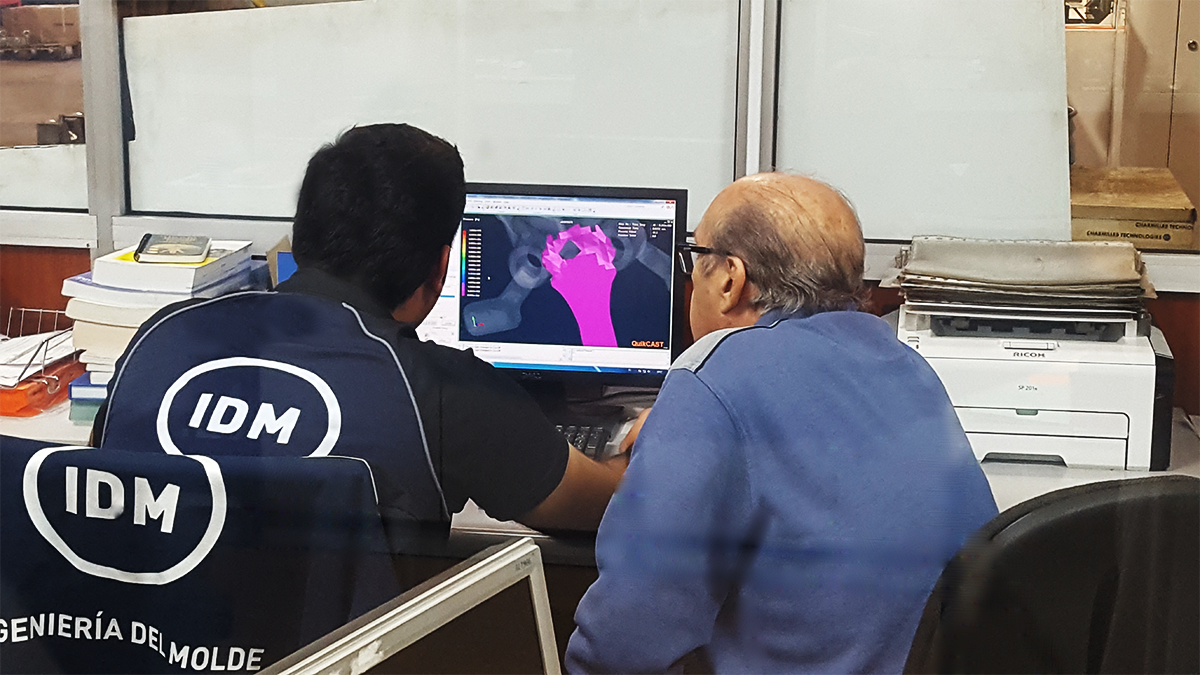

Advisory Service

At our company, we are here to help our clients bring their ideas to life. For this reason, we offer excellent service with comprehensive advice to help you make decisions.

Verification and Monitoring

At Mold Engineering, we verify molds, thus confirming the accuracy of their processing before delivery to the client.

In addition, to properly monitor each project, we maintain a detailed history of each completed project for review at any time.

Completed IDM Projects

DO YOU WANT TO CREATE A PROJECT WITH US?

Would you like more information about our services?